How a 60-degree upward camera tilt can support safer, faster, more efficient inspections

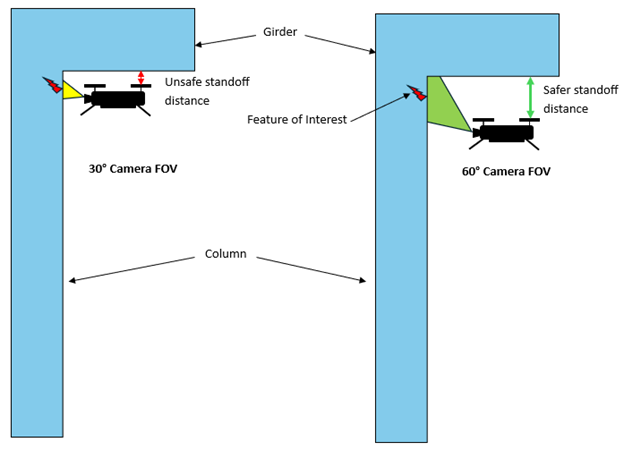

When performing infrastructure inspections, the ability to see every bolt, weld, rivet, or joint is crucial. While drones have revolutionized this field by featuring cameras that point downwards to cover large areas in short periods of time, not all drones are created equal. This is because, during inspections, it is often required to tilt the drone camera upwards to capture images of certain features. Most aerial drones can only tilt their cameras up to a 30-degree angle, which limits their effectiveness when inspecting structures from below. This restriction often means inspectors can’t get a clear view of the underside of bridges, overpasses, and tunnel roofs – areas where critical issues frequently develop. That’s where our specialized drones come in, offering a game-changing 60-degree upward camera tilt that effectively doubles the field of view (FOV) of the camera. This unique capability allows us to get very close to the underside of infrastructure, capturing high-quality visual data of areas that are typically hard to reach or see.

By seeing more because of a wider FOV, we can provide a more thorough, efficient inspection, helping to spot potential problems early and ensuring the safety and longevity of vital structures. The advantages of this 60-degree tilt are numerous. For bridges, tunnels, overpasses, and industrial plants, we can fly directly underneath and capture detailed images of support structures, looking for signs of wear, corrosion, or structural damage. During flight, our drones cameras can be maneuvered at various angles as needed, providing a comprehensive view of the entire underside without the need for lane closures or expensive lifting equipment.

In tunnel inspections, for example, the increased tilt allows us to examine roof conditions more closely, identifying potential weak spots or water infiltration issues that might be missed by standard drones or ground-based inspections. This enhanced capability doesn’t just improve the quality of inspections – it also increases efficiency and safety. Traditional inspection methods often require workers to use bucket trucks, scaffolding, or rope access to reach these complex areas. These methods are time-consuming, expensive, and can put workers at risk. Our 60-degree camera tilt drones eliminate these risks, allowing inspectors to stay safely on the ground while the drone does the dangerous work.

The ability to compare current conditions with historical data can help predict future issues before they become critical, potentially saving millions in repair costs and preventing infrastructure failures. Aging infrastructure is a growing concern, and the importance of thorough, efficient inspections cannot be overstated. Our 60-degree camera tilt drones represent a significant leap forward in this crucial field. By providing a more transparent, more comprehensive view of hard-to-reach areas, we’re not just changing how inspections are done – we’re helping to ensure the safety and longevity of the structures we all rely on every day.

Why is a wider FOV better when inspecting infrastructure with an aerial drone?

A wider field of view (FOV) is significantly advantageous when inspecting infrastructure like bridges, overpasses, tunnels and industrial plants with aerial drones for several key reasons:

Improved Efficiency

Drones with a wider FOV capture more of the structure in a single pass, reducing the number of flights needed to inspect the entire structure. This increased coverage per flight translates to:

• Shorter inspection times for a given structure

• Reduced battery consumption, allowing coverage of more structures in a given period

Enhanced Data Collection

With a wider FOV, drones can gather more comprehensive visual data of the structure:

• Capture larger sections of the structure in each image or video frame

• Provide better context for identifying and assessing structural issues

• Greater volume of data acquisition per flight

Increased Safety

By requiring fewer passes and allowing the drone to maintain a safer distance from the structure, a wider FOV contributes to:

• Greater standoff distances, with reduced risk of collisions (see figure above)

• Minimized need for close-up inspections in hazardous areas

• Enhanced overall safety of the inspection process

Improved Visualization

A wider FOV helps in maintaining spatial awareness and context during inspections:

• Easier identification of the defects or issue and it’s relative location to nearby features

• Better understanding of how different parts of the structure relate to each other

• More accurate assessment of the overall condition of the bridge

Time and Cost Savings

The combination of efficiency and comprehensive data collection leads to significant benefits:

• Faster completion of inspections, reducing disruption to traffic

• Lower labor costs due to shorter inspection times

• Decreased need for multiple inspection sessions

In conclusion, a wider field of view in drone-based inspections offers an excellent balance of efficiency, safety, and data quality, making it an invaluable feature for infrastructure inspection drones.